Are you ready to dive into the fascinating world of welding? Brace yourself for a journey through time, where ancient civilizations heated metals and bonded them together with skillful precision. From the Bronze Age to the Industrial Revolution, humans have been harnessing the power of fire and metal to create extraordinary structures and weapons. Today, with over 90 different welding processes and cutting-edge technology at our fingertips, we continue to push the boundaries of what is possible. So grab your helmet and let’s explore the captivating history of welding: when it all began and how it was invented.

Early Development of Welding Techniques

Gas welding and cutting were developed in the late 1800s as part of the early development of welding techniques. This period saw significant advancements in welding technology. One key discovery was made by Edmund Davy, who discovered acetylene in 1836. The popularity of arc lighting also played a role in the development of welding techniques during this time. Gas welding and cutting methods were introduced, allowing for more precise and efficient joining of metal pieces. Additionally, resistance welding processes such as spot welding and seam welding were developed, providing alternative methods for joining metals. Finally, in 1920, P.O. Nobel invented automatic welding, revolutionizing the industry by increasing productivity and efficiency. These developments set the stage for further advancements in welding techniques to come.

Ancient Welding Methods

To join pieces of metal together in ancient times, you would have used charcoal to pressure-weld swords and fused metals like copper, bronze, silver, gold, and iron. These techniques were prevalent during the Bronze Age and Iron Age. Metal fusion methods were developed by skilled craftsmen who used ancient welding tools to create strong and durable connections between different metals. Historical welding practices varied across different civilizations, with each culture contributing its own unique approach to the art of joining metals. The use of heat and pressure allowed ancient welders to create intricate designs and functional objects that served various purposes in society. Today, we can appreciate the ingenuity and skill of those early metalworkers who laid the foundation for modern welding techniques.

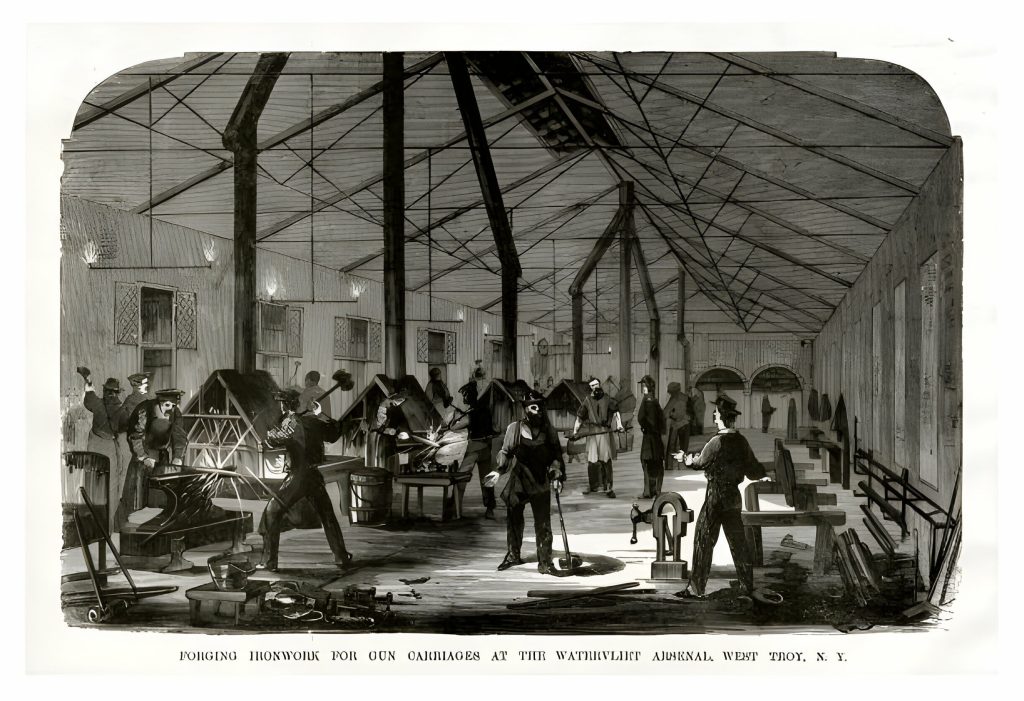

The Industrial Revolution and Modern Welding

During the Industrial Revolution, you would have witnessed significant advancements in welding techniques that revolutionized the manufacturing industry. The impact of automation and robotic welding became increasingly evident during this time. These new technologies allowed for more precise and efficient welding processes, leading to increased productivity and reduced labor costs. Additionally, there was a growing emphasis on welding safety as regulations were put in place to protect workers from hazardous conditions. The aerospace industry began to heavily rely on welding for the construction of aircraft components, ensuring their strength and durability. Furthermore, underwater welding emerged as a specialized field, enabling repairs and maintenance to be performed on structures such as oil rigs and ships beneath the water’s surface. Overall, these advancements in welding during the Industrial Revolution paved the way for modern manufacturing practices and expanded the possibilities of what could be achieved through this essential process.

Advancements in Welding Techniques

The development of new welding processes in the mid-20th century brought about significant advancements in the field, such as the introduction of smaller-diameter electrode wires and refined power supplies. These advancements revolutionized the way welding was done, improving productivity, safety, and automation. Here are four key advancements that occurred during this period:

- Smaller-Diameter Electrode Wires: The introduction of smaller electrode wires allowed for more precise and intricate welds to be made. This advancement enabled welders to work on thinner materials with greater accuracy.

- Refined Power Supplies: The refinement of power supplies resulted in better control over heat input during welding. This not only improved the quality of welds but also enhanced safety by reducing the risk of overheating and material distortion.

- Automation: Advancements in welding technology led to the development of automated welding systems. These systems increased productivity by allowing for continuous operation without human intervention.

- Improved Materials: Alongside technological advancements, there were also improvements in welding materials themselves. New alloys and coatings were developed that further enhanced the strength and durability of welded joints.

Overall, these advancements have played a crucial role in making welding more efficient, reliable, and versatile across various industries.

Evolution of Welding Processes

Advancements in welding techniques during the mid-20th century brought about significant changes, such as the introduction of smaller-diameter electrode wires and refined power supplies. These evolutionary changes in welding processes marked a turning point in the industry, leading to technological advancements that revolutionized the way we join metal. With historical transformations taking place, innovative approaches emerged, allowing for more precise and efficient welding methods. Progressive developments in welding technology made it possible to achieve high-quality welds on thin materials and enabled all-position welding. The introduction of inert gas with small amounts of oxygen provided a spray-type arc transfer, further improving the welding process. Additionally, new processes like plasma arc welding and electron beam welding offered higher temperatures and focused beams of electrons for even more precise results. Overall, these advancements have propelled the field of welding into a new era of efficiency and accuracy.

Innovations in Welding Technology

You can explore the latest innovations in welding technology that have revolutionized the industry. Here are four advancements that have shaped the field:

- Automation: Welding processes have become more automated, with robots taking over repetitive tasks and increasing efficiency.

- Materials: Innovations in welding techniques have allowed for the joining of a wide range of materials, including non-ferrous metals and composites.

- Robotics: The use of robotics has improved precision and accuracy in welding, resulting in higher quality welds.

- Safety: With advancements in safety equipment and protocols, welders can now work in safer environments, reducing the risk of accidents and injuries.

These innovations continue to push the boundaries of what is possible in welding, making it a dynamic and evolving field.

Impact of World Wars on Welding

During World Wars I and II, welding saw a significant increase in its use for weapons manufacturing and transportation needs. Wartime welding played a crucial role in the production of weapons, as it allowed for the joining of metal components to create tanks, airplanes, and ships. Welding advancements during this time period included the development of new techniques and equipment that improved the efficiency and accuracy of welding processes. Transportation welding during wars became essential for repairing damaged vehicles and ships on the battlefield, ensuring that they could continue to be used effectively. The impact of world wars on welding cannot be overstated, as it propelled the industry forward and led to further innovations in welding technology that are still used today.

Contemporary Welding and Future Prospects

Looking ahead, there are exciting future prospects for the field of welding. Here are four advancements that will shape the future of welding:

- Robotic Welding: Advances in robotics technology will lead to increased automation in welding processes. Robots can perform repetitive tasks with greater precision and speed, improving productivity and reducing human error.

- 3D Printing: The integration of 3D printing technology with welding opens up new possibilities in manufacturing complex metal structures. This combination allows for the creation of intricate designs and customized parts, revolutionizing industries such as aerospace and automotive.

- Laser Welding: Laser welding offers several advantages over traditional methods, including higher precision, minimal heat input, and faster processing times. As laser technology continues to improve, it will become more widely adopted in various industries for its versatility and efficiency.

- Underwater Welding: With the increasing demand for offshore infrastructure development, underwater welding plays a crucial role in maintaining and repairing underwater structures. Advancements in diving equipment and specialized techniques will enhance safety and efficiency in this challenging environment.

As these future advancements continue to unfold, the field of welding is poised for even greater innovation and growth.